Continuous Algal Production Systems

How

do you grow algae in your hatchery? How

do you grow algae in your hatchery?

If you answer 'Yes' to any of these questions you need to

click here for help!

Are you still using a batch system, with all the time-consuming

repetitive work which this involves, or struggling to maintain

sterile conditions economically using filters?

Is output limited by algae production, which you cannot expand

for reasons of manpower, space and cost?

Do you have several people working nearly full-time on the

phytoplankton, upon which your production depends, whose holidays

or sick-leave bring you close to crisis?

Are half your algal cultures unready to be harvested at any

one time?

Do you spend a small fortune on heating then pour large quantities

of warmed water down the drain?

Do your cultures vary widely in quality, from the time when

you can start cropping them until the moment they have to

be dumped?

And do they sometimes fail just when you need them most?

View case

studies >>>

Rotifer Production

Seasalter

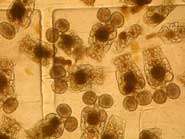

Shellfish continuous algae systems used all over the world,

mainly by shellfish hatcheries, have seen some new applications

recently with the introduction of rotifer culture. (Species

illustrated Brachionus plicatillis). Seasalter

Shellfish continuous algae systems used all over the world,

mainly by shellfish hatcheries, have seen some new applications

recently with the introduction of rotifer culture. (Species

illustrated Brachionus plicatillis).

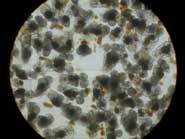

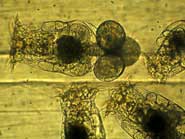

Rotifers are cultivated in an open flow system. In fact the

flow is just neat algae culture. As the algae system uses

only pasteurized water the rotifer cultures are free of any

harmful contamination such as vibrios, viruses or ciliates.

A typical rotifer culture will reach a density of 1500 to

2000 rotifers per ml. Everyday 50% of the volume of the culture

can be harvested. The following day as the culture has reach

its overflow level, the density is back to its normal level

and the process can be repeated indefinitely.

With the shortage of Artemia availability worldwide, high

quality algae and rotifer production seems to be the obvious

answer.

Fish

fry need for their development a diet rich in polyunsaturated

fatty acids (PUFA) such as: Fish

fry need for their development a diet rich in polyunsaturated

fatty acids (PUFA) such as:

AA (arachidonic acid) 20:4(n-6)

EPA (eicosapentaenoic acid) 20:5(n-3)

DHA (docosahexaenoic acid) 22:6(n-3)

These essential fatty acids (EFA) cannot be synthesized de

novo by the fish but are naturally present in the algae species

grown in the bags system like Chaetoceros, Isochrisis, Pavlova

or Tetraselmis.

But what is crucial for good development and the survival

of the fry is not just the presence of these PUFA but their

ratio between one and other.

By

its flexibility the bag system allow you to grow as many different

species as you have bags in your system if you whish to do

so. By

its flexibility the bag system allow you to grow as many different

species as you have bags in your system if you whish to do

so.

It then very easy once you now the EFA composition of the

different algae species to arrange a balanced diet close to

the required ratio of PUFA you are looking for.

This very simple yet very clever way of growing rotifers

will help you to get away from yeast and other food enrichment

additives that usually leads to poor quality live food.

Soon a new Cod farm situated in Norway will also be able

to benefit from the quality rotifers produced with the help

of a Seacaps continuous algae system. Each system supplied

comes with full staff training and full back up.

|